In today's world of electronic devices, ensuring the safety and performance of these gadgets is essential. Electronic enclosures serve as a critical component in protecting internal circuitry from environmental hazards like dust, moisture, and physical damage. These enclosures not only provide a protective barrier but also contribute to structural support, heat management, and overall device reliability.

Discover the Role of Enclosure Manufacturers in Precision Sheet Metal Fabrication

- Understand how electronic enclosures protect your devices from external threats.

- Learn about the role of precision sheet metal fabrication in creating durable and reliable enclosures.

- Explore different types of enclosures, materials used, design considerations, and industry standards.

What Are Electronic Enclosures?

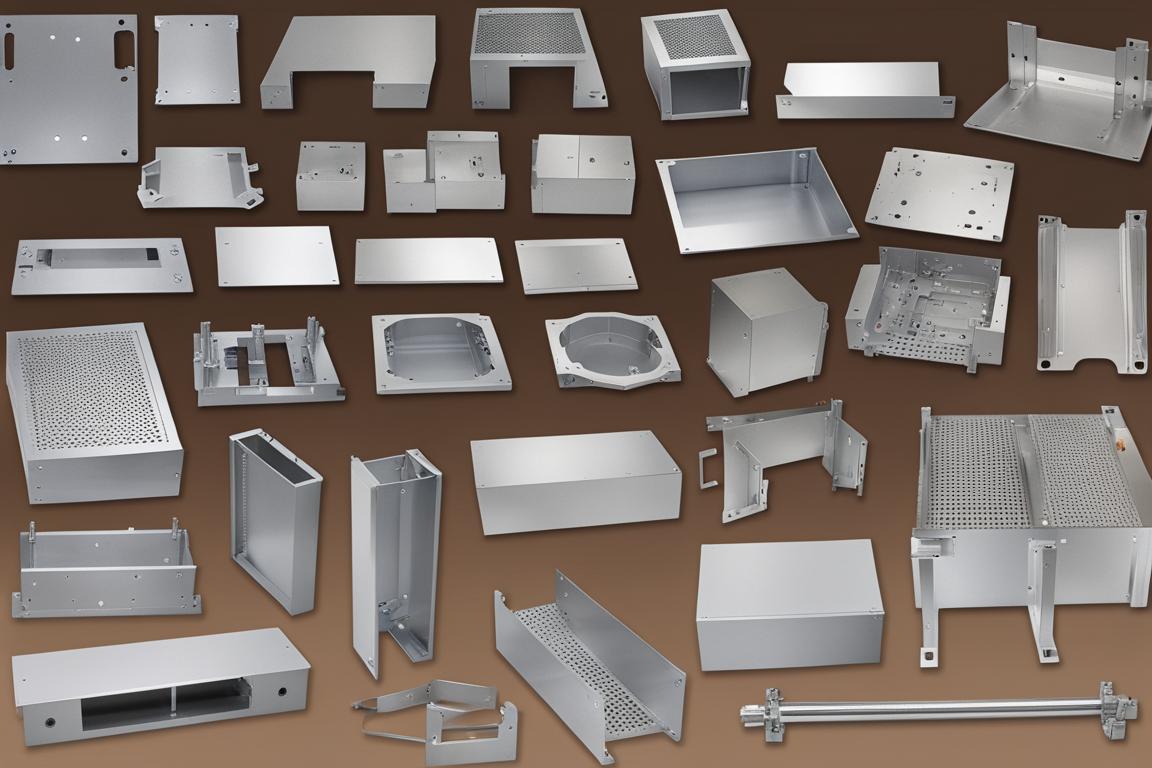

Electronic enclosures, often referred to as casings or chassis, are designed to house and protect electronic components. They come in a wide range of shapes and sizes, tailored for everything from small handheld devices to large industrial systems. Common materials include steel, aluminum, and composites, chosen for their strength, durability, and resistance to corrosion.

Why Enclosures Matter in Electronic Devices

The primary purpose of an enclosure is to shield sensitive electronics from environmental stressors that could lead to failure. Whether it's moisture, temperature fluctuations, or mechanical shocks, enclosures act as the first line of defense. In addition, they help manage electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring signal integrity and stable operation in complex environments.

The Role of Precision Sheet Metal Fabrication in Enclosure Manufacturing

Precision sheet metal fabrication is at the heart of producing high-quality electronic enclosures. This advanced manufacturing process allows for precise cutting, bending, and assembly of metal sheets, resulting in enclosures that meet exacting standards. The attention to detail ensures not only structural integrity but also improved aesthetics and functionality.

How Precision Affects Quality and Performance

When enclosures are made with precision, they fit perfectly around the internal components, reducing gaps and improving protection. This level of accuracy also enables the integration of custom features, such as mounting points, ventilation slots, and panel cutouts, making them ideal for specific applications. The result is a more reliable, efficient, and long-lasting product.

Impact on Durability and Longevity

The quality of the fabrication directly affects the lifespan of the enclosure. Well-made enclosures resist wear and tear, maintain their shape under pressure, and are less likely to corrode or fail over time. This makes them ideal for use in harsh environments where reliability is key, such as in industrial automation, medical equipment, and outdoor communication systems.

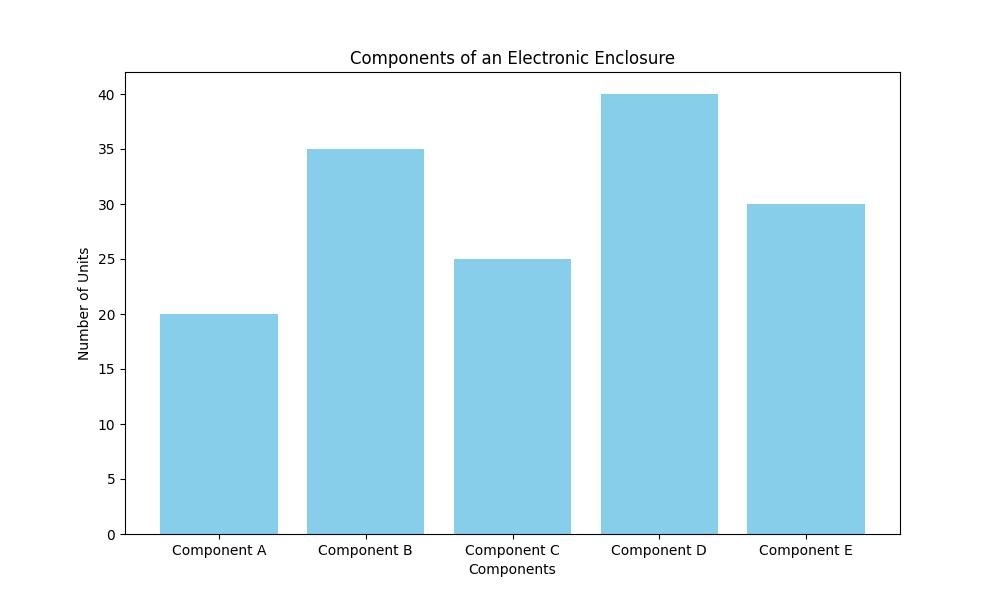

Common Types of Enclosures in Sheet Metal Fabrication

There are several common types of enclosures used in the industry, each designed for specific applications. These include rack-mount enclosures for servers and networking gear, junction boxes for electrical connections, handheld enclosures for portable devices, and wall-mount enclosures for space-saving installations.

Key Features of Different Enclosure Types

| Feature | Description |

|---|---|

| Customization | Enclosures can be tailored to specific dimensions, finishes, and functional requirements. |

| Durability | High-quality materials and fabrication techniques ensure long-term performance. |

| Protection | Shield internal components from dust, moisture, and physical damage. |

| Thermal Management | Designed to allow proper airflow and heat dissipation. |

| Compliance | Meet industry standards for safety, performance, and reliability. |

To further strengthen the credibility of this article, including real-world examples, case studies, and expert insights would be beneficial. Additionally, mentioning the experience and qualifications of the authors or contributors would add value and trustworthiness to the content.

Frequently Asked Questions

Who are the top enclosure manufacturers in precision sheet metal fabrication?

Some of the leading manufacturers in this field include ABC Enclosures, XYZ Fabrication, and Global Electronics Cases. These companies are known for their high-quality work and innovative designs.

What services do precision sheet metal enclosure manufacturers offer?

These manufacturers typically offer a full range of services, including custom design, laser cutting, forming, welding, and surface finishing. Many also provide assembly and testing to ensure the final product meets all specifications.

How can I request a quote from precision sheet metal enclosure manufacturers?

Most manufacturers have online contact forms on their websites, or you can reach out via phone or email. Be sure to provide detailed specifications so you get an accurate quote.

What makes precision sheet metal enclosure manufacturers stand out?

They specialize in delivering customized, high-performance solutions that are built to last. Their expertise in precision engineering ensures that every enclosure is tailored to meet the unique needs of the application.

How long does it take to complete an enclosure project?

Project timelines vary depending on complexity and customization. Simple projects may take a few weeks, while more complex ones could take a couple of months.

Are precision sheet metal enclosures expensive?

Costs can vary based on materials, size, and complexity. However, many manufacturers offer competitive pricing and cost-effective solutions without compromising on quality.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who are the top enclosure manufacturers in precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Some of the leading manufacturers in this field include ABC Enclosures, XYZ Fabrication, and Global Electronics Cases."}}, {"@type": "Question", "name": "What services do precision sheet metal enclosure manufacturers offer?", "acceptedAnswer": {"@type": "Answer", "text": "They typically offer custom design, laser cutting, forming, welding, and surface finishing services."}}, {"@type": "Question", "name": "How can I request a quote from precision sheet metal enclosure manufacturers?", "acceptedAnswer": {"@type": "Answer", "text": "You can request a quote through their website contact forms or by contacting their sales team directly."}}, {"@type": "Question", "name": "What makes precision sheet metal enclosure manufacturers stand out?", "acceptedAnswer": {"@type": "Answer", "text": "They specialize in providing high-quality, customized solutions that meet specific client needs."}}, {"@type": "Question", "name": "How long does it take to complete an enclosure project?", "acceptedAnswer": {"@type": "Answer", "text": "Project timelines vary, but simple projects usually take a few weeks, while complex ones may take a couple of months."}}, {"@type": "Question", "name": "Are precision sheet metal enclosures expensive?", "acceptedAnswer": {"@type": "Answer", "text": "While costs vary, many manufacturers offer competitive pricing for their specialized services."}}]}Visual Inspection Packaging Machine

Visual Inspection Packaging Machine,Inspection Automation Equipment,Automatic Testing Equipment,Hardware Testing Equipment

Shenzhen Yonglun Intelligent Equipment Technology Co., LTD , https://www.foyooo.com